- krofta@kroftaengineering.com

- Durga Bhavan A-68, FIEE Complex, Okhla Industrial Area Phase – II, N.D – 110 020

API For Oil Removal

API For Oil Removal

An API oil-water separator

is a device designed to separate gross amounts of oil and suspended solids from the wastewater effluents of petroleum refineries, petrochemical and chemical plants, natural gas processing plants and other industrial sources.The name is derived from the fact that such separators are designed according to standards published by the American Petroleum Institute (API).

The API separator was developed about 75 years ago by the API and the Rex Chain Belt Company. The API separator is normally the first, and most important, wastewater treatment step in petroleum refineries. The primary function of a properly designed API separator is to remove the majority of oil and suspended solids from refinery wastewater prior to subsequent downstream wastewater treatment processes.

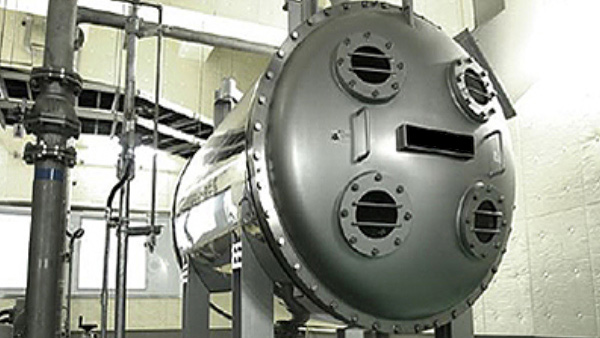

Krofta is a leading source for API Separator design, engineering, and manufacturing services. A well-designed, properly functioning API Separator is a tremendous piece of wastewater process equipment for refineries, chemical plants, power plants, and many other heavy-duty industrial facilities. They are designed per American Petroleum Institute standards (API) for above and below ground installations.

A gravity differential settling is used to separate the oil from water. Krofta engineers will evaluate the type and state of the oil and the characteristics of the waste stream to determine the proper design and size of the separator. Oil globule size, specific gravity of the oil and wastewater, temperature, and viscosity should be considered. Suspended solids will also be settled from the wastewater and provisions of this will be part of the design.

The API separator works on the principle of Stokes Law, which defines the rise velocity of an oil particle based on its density and size. Typically, the difference between the specific gravity of oil to be separated and water is much closer than the specific gravity of the suspended solids and water.

Don't guess on the sizing------call us. We do this every day.

Anita

Anita