- krofta@kroftaengineering.com

- Durga Bhavan A-68, FIEE Complex, Okhla Industrial Area Phase – II, N.D – 110 020

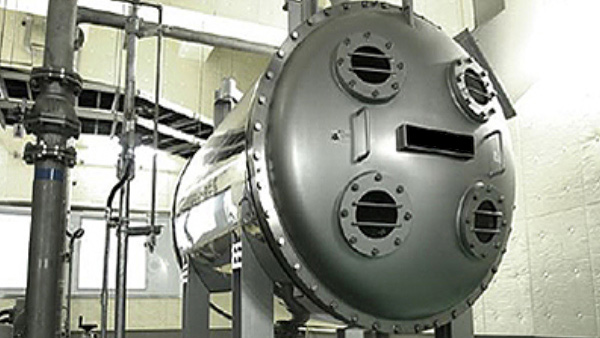

Daf

Daf

Here’s how this highly efficient Dissolved Air Flotation (DAF) process works:

Water enters the DAF system through the influent header box to reduce the water’s velocity and distribute it across the vessel's length. To optimize the treatment process, we design the influent header box with multiple injection points, allowing the introduction of whitewater — a highly saturated pressurized stream of air and DAF effluent that sometimes includes a flocculant.

The whitewater forms micro-bubbles and as the wastewater enters the flotation zone, the micro-bubbles attach to the particle surface, lowering the particle density enough to cause suspended solids, fats, oils, greases, and non-soluble organics to separate from the wastewater and rise to the surface. The now dissolved solids, fats, oils, greases, and non-soluble organics are skimmed and removed by a chain-and-flight skimmer into the sludge hopper.

This DAF is specifically designed to excel at treating primary metal production wastewater. The PMP DAF offers highly efficient removal rates, low cost of ownership, and improved performance compared to conventional technologies. A durable construction ensures corrosion resistance in the harshest processing environments.

Anita

Anita